The automotive industry is one of the most complex and competitive sectors in the global economy. From raw material sourcing and component manufacturing to vehicle assembly, distribution, and after-sales service, automotive companies manage highly intricate operations. In this environment, Enterprise Resource Planning (ERP) systems play a critical role in enabling efficiency, visibility, and scalability. ERP for automotive companies is no longer a back-office tool—it is a strategic platform that integrates processes, data, and decision-making across the entire value chain.

The Unique Challenges of the Automotive Industry

Automotive companies face challenges that are distinct from many other industries. These include:

- Complex supply chains involving thousands of suppliers across multiple countries

- Just-in-Time (JIT) manufacturing requirements that demand precise coordination

- Strict quality and compliance standards, such as ISO/TS and IATF 16949

- High product variability, including different models, trims, and configurations

- Rapid technological change, especially with electric vehicles (EVs), autonomous driving, and connected cars

Traditional siloed systems struggle to keep up with this level of complexity. ERP systems are designed to unify operations, reduce inefficiencies, and provide real-time insights that automotive companies need to remain competitive.

What Is an ERP System in the Automotive Context?

An ERP system is an integrated software platform that manages core business processes such as finance, manufacturing, procurement, inventory, human resources, and sales. For automotive companies, ERP solutions are often enhanced with industry-specific capabilities, including:

- Bill of Materials (BOM) management for complex assemblies

- Production planning and scheduling

- Supplier collaboration and EDI integration

- Quality management and traceability

- Warranty and after-sales service management

By consolidating data into a single source of truth, ERP systems help automotive organizations improve accuracy, coordination, and decision-making.

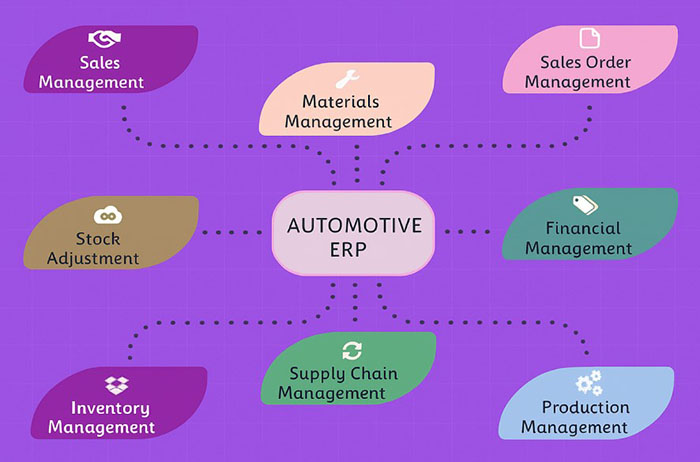

Key ERP Modules for Automotive Companies

1. Manufacturing and Production Planning

Manufacturing is at the heart of the automotive industry. ERP systems support advanced production planning, capacity management, and shop floor control. Automotive ERP solutions can handle multi-level BOMs, sequence-dependent setups, and mixed-model production lines.

With real-time production data, managers can quickly identify bottlenecks, reduce downtime, and optimize throughput. This is especially important in lean manufacturing environments where delays can disrupt the entire supply chain.

2. Supply Chain and Inventory Management

Automotive supply chains are global and highly interdependent. ERP systems enable companies to manage procurement, supplier performance, inventory levels, and logistics from a single platform. Features such as demand forecasting and material requirements planning (MRP) help ensure that the right parts are available at the right time.

Effective ERP-driven inventory management reduces excess stock, minimizes shortages, and supports Just-in-Time delivery models—critical factors for cost control and operational efficiency.

3. Quality Management and Traceability

Quality is non-negotiable in the automotive industry. ERP systems provide tools for quality planning, inspection, non-conformance management, and corrective actions. Many automotive ERP solutions also offer full traceability, allowing companies to track components from suppliers through production and into finished vehicles.

This level of traceability is essential for regulatory compliance, recalls, and continuous improvement initiatives.

4. Finance and Cost Control

Automotive manufacturing involves significant capital investment and tight margins. ERP systems integrate financial management with operational data, enabling accurate cost tracking at every stage of production. Companies can analyze product profitability, manage budgets, and comply with international accounting standards more effectively.

By linking finance with manufacturing and supply chain data, ERP systems provide a clear picture of where costs are incurred and where efficiencies can be gained.

5. Sales, Distribution, and After-Sales Service

ERP systems also support downstream activities such as order management, distribution, and after-sales service. Automotive companies can manage dealer networks, pricing, and promotions while ensuring timely order fulfillment.

In after-sales service, ERP solutions help track warranties, service history, spare parts inventory, and customer feedback. This improves customer satisfaction and creates new revenue opportunities through service and maintenance offerings.

Benefits of ERP for Automotive Companies

Implementing an ERP system delivers both operational and strategic benefits, including:

- Improved operational efficiency through process automation and integration

- Enhanced visibility across the supply chain and production lifecycle

- Better decision-making based on real-time, accurate data

- Reduced costs through optimized inventory and resource utilization

- Regulatory compliance with industry standards and reporting requirements

- Scalability to support growth, new models, and global expansion

For automotive companies navigating digital transformation, ERP serves as the backbone that connects emerging technologies such as IoT, AI, and advanced analytics.

ERP and the Future of the Automotive Industry

The automotive sector is undergoing a major transformation driven by electrification, connectivity, and sustainability. ERP systems are evolving to support these trends. Modern cloud-based ERP solutions offer greater flexibility, faster deployment, and easier integration with advanced technologies.

For example, ERP systems can integrate with IoT sensors on the factory floor to enable predictive maintenance, or with analytics platforms to optimize energy usage and reduce carbon footprints. As automotive companies transition to electric vehicles, ERP systems help manage new supply chains, battery tracking, and regulatory reporting.

Choosing the Right ERP Solution

Selecting the right ERP system is a strategic decision. Automotive companies should consider factors such as:

- Industry-specific functionality

- Scalability and global support

- Integration capabilities with existing systems

- Cloud vs. on-premise deployment options

- Vendor experience in the automotive sector

A successful ERP implementation also requires strong change management, employee training, and ongoing system optimization.

Conclusion

ERP for automotive companies is no longer optional—it is a critical enabler of efficiency, quality, and innovation. In an industry defined by complexity and rapid change, ERP systems provide the integrated foundation needed to manage operations end-to-end. By adopting the right ERP solution, automotive companies can improve competitiveness, respond faster to market demands, and build a resilient future in an evolving global landscape.