Mastering Efficiency: The Dynamics of MRP Software in Modern Business

In the intricate landscape of modern business operations, where efficiency and precision are paramount, the role of Material Requirements Planning (MRP) software stands out as a key enabler. MRP software serves as a comprehensive solution designed to optimize the management of materials, production schedules, and inventory, facilitating a streamlined and cost-effective production process. In this article, we delve into the world of MRP software, exploring its functionalities, advantages, and the transformative impact it brings to businesses across various industries.

Decoding MRP Software

1. Material Planning and Procurement: At its core, MRP software focuses on material planning and procurement. It assesses the demand for finished products, considers the existing inventory levels, and generates comprehensive material requirements plans. This ensures that businesses have the right materials available at the right time to meet production demands.

2. Production Scheduling: MRP software excels in production scheduling. By considering factors such as lead times, production capacities, and order priorities, the software generates optimized production schedules. This not only maximizes the utilization of resources but also minimizes idle time, contributing to overall operational efficiency.

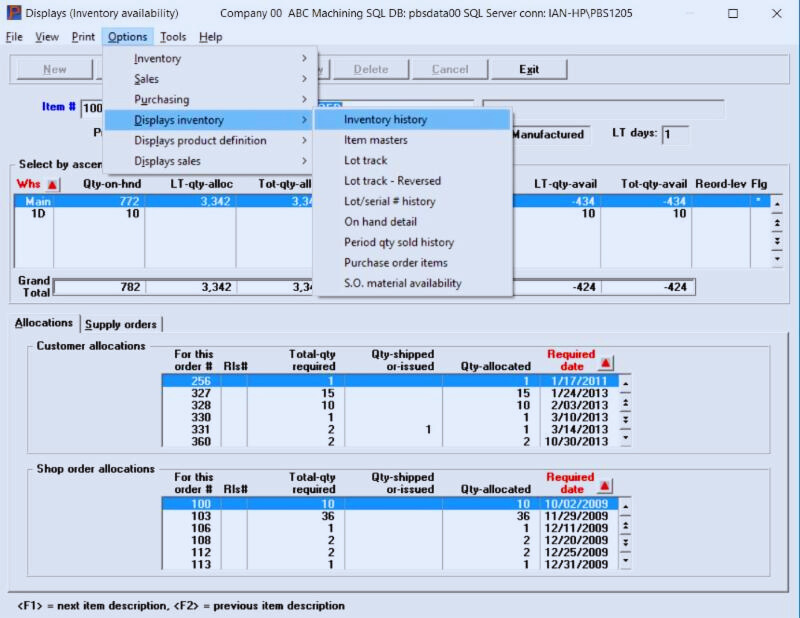

3. Inventory Optimization: Efficient inventory management is a hallmark of MRP software. The software monitors inventory levels in real-time, automatically triggering reorders when stock levels fall below predetermined thresholds. This prevents stockouts, minimizes excess inventory, and ensures a balanced and cost-effective supply chain.

Key Functionalities of MRP Software

4. Bill of Materials (BOM) Management: MRP software incorporates Bill of Materials management, providing a detailed list of components and subassemblies required for the production of finished goods. This ensures accurate planning and procurement of all necessary materials.

5. Real-Time Data Insights: The ability to access real-time data is a key strength of MRP software. Businesses can gain instant insights into material availability, production progress, and inventory status. This real-time visibility is instrumental in making informed decisions and responding promptly to changing market conditions.

6. Demand Forecasting: MRP software often includes demand forecasting modules. By analyzing historical data and market trends, the software helps businesses predict future demand, enabling more accurate material planning and production scheduling.

Advantages of MRP Software

7. Improved Production Planning: MRP software significantly improves production planning accuracy. By considering various factors, including demand fluctuations and lead times, businesses can create realistic production schedules that align with market demand, minimizing delays and optimizing resource utilization.

8. Cost Savings: Efficient material planning and inventory management contribute to cost savings. MRP software helps businesses avoid excess inventory holding costs, reduces the risk of stockouts, and minimizes production inefficiencies, ultimately leading to overall cost-effectiveness.

9. Enhanced Customer Satisfaction: Accurate production schedules and timely order fulfillment contribute to enhanced customer satisfaction. MRP software ensures that businesses can meet customer demands promptly, fostering positive relationships and loyalty.

Considerations When Implementing MRP Software

10. Integration with Existing Systems: When implementing MRP software, compatibility and integration with existing systems, such as Enterprise Resource Planning (ERP) or Customer Relationship Management (CRM) software, should be considered to maintain a cohesive and connected technology ecosystem.

11. User Training: Effective use of MRP software requires thorough user training. Businesses should invest in training programs to ensure that employees can utilize the full capabilities of the software, maximizing its impact on daily operations.

12. Scalability: As businesses grow, MRP software should be scalable to accommodate increased data volumes, users, and additional functionalities. Scalability ensures that the software remains effective and aligned with evolving business needs.

The Future of MRP Software

As technology continues to advance, the future of MRP software holds exciting possibilities. Trends such as artificial intelligence, machine learning, and increased connectivity with Internet of Things (IoT) devices are anticipated to further enhance the capabilities of MRP software, making it even more intelligent and responsive to changing manufacturing landscapes.

In Conclusion: Orchestrating Precision in Production

In conclusion, MRP software emerges as a critical tool for businesses seeking precision and efficiency in their production processes. Its ability to optimize material planning, streamline production schedules, and enhance inventory management positions it as a strategic asset in the modern business toolkit. As industries continue to evolve, the adoption of MRP software becomes not just a choice but a fundamental step toward orchestrating precision in production, minimizing costs, and driving sustainable business success.