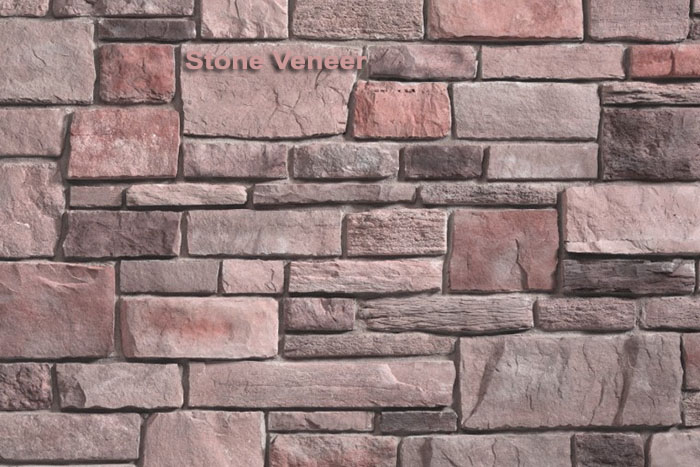

Stone Veneer

Stone veneer has become one of the most versatile and sought-after materials in modern construction and interior design. Valued for its natural appearance, durability, and adaptability, stone veneer bridges the gap between traditional stone masonry and contemporary building needs. Whether used on exterior façades, interior feature walls, fireplaces, or commercial spaces, stone veneer offers the timeless beauty of natural stone without many of the limitations associated with full-depth stone. This article explores what stone veneer is, its types, benefits, applications, installation considerations, maintenance, and future trends.

What Is Stone Veneer?

Stone veneer is a thin layer of stone or stone-like material designed to replicate the look of full-thickness natural stone. Unlike traditional stone masonry, which relies on heavy blocks that are structural in nature, stone veneer is primarily decorative. It is applied to surfaces such as concrete, brick, wood framing, or metal panels to enhance visual appeal while minimizing weight and cost.

Stone veneer generally ranges from 1 to 2 inches in thickness, making it significantly lighter than solid stone. This reduced thickness allows it to be installed on a wide variety of surfaces without requiring additional structural reinforcement, which is a major reason for its popularity in both residential and commercial projects.

Types of Stone Veneer

Stone veneer can be broadly categorized into natural stone veneer and manufactured stone veneer. Each type has its own characteristics, advantages, and ideal use cases.

Natural Stone Veneer

Natural stone veneer is made from real stone that is quarried and cut into thin slices. Common stone types include limestone, slate, granite, quartzite, and sandstone. Because it is genuine stone, each piece has unique color variations, textures, and patterns, giving installations a truly authentic appearance.

Natural stone veneer is highly durable, resistant to weathering, and capable of aging gracefully over time. However, it is typically more expensive than manufactured alternatives and may require skilled labor for proper installation.

Manufactured Stone Veneer

Manufactured stone veneer, also known as cultured stone or faux stone, is made from a mixture of cement, aggregates, and iron oxide pigments. These materials are molded to replicate the look of natural stone with remarkable accuracy.

Manufactured stone veneer is lighter, more affordable, and often easier to install than natural stone veneer. It also offers greater consistency in color and shape, which can be beneficial for certain design styles. While modern manufacturing techniques have significantly improved realism, some purists still prefer the subtle imperfections of natural stone.

Benefits of Stone Veneer

Stone veneer offers a wide range of benefits that make it an attractive choice for homeowners, designers, and builders alike.

Aesthetic Appeal

One of the most compelling advantages of stone veneer is its visual impact. Stone has long been associated with strength, elegance, and permanence. Stone veneer captures these qualities while allowing greater design flexibility. It can create rustic, traditional, modern, or even minimalist looks depending on the stone type, color, and layout.

Lightweight Construction

Because stone veneer is much lighter than full-depth stone, it reduces structural load. This makes it suitable for renovations, upper floors, and interior walls where traditional stone would be impractical or impossible to use.

Cost Efficiency

Stone veneer is generally more cost-effective than solid stone construction. Savings come from reduced material costs, lower transportation expenses, and faster installation times. Manufactured stone veneer, in particular, provides a high-end appearance at a fraction of the cost of natural stone.

Versatility

Stone veneer can be used in a wide range of applications, from exterior walls and columns to interior fireplaces, kitchens, bathrooms, and accent walls. It works well in residential homes, offices, hotels, restaurants, and retail spaces.

Durability

When properly installed, stone veneer is highly durable and resistant to moisture, temperature fluctuations, and impact. Natural stone veneer, in particular, can last for decades with minimal maintenance.

Common Applications of Stone Veneer

Stone veneer is valued not only for its beauty but also for its adaptability across different spaces.

Exterior Applications

On building exteriors, stone veneer is often used to enhance curb appeal. It can be applied to entire façades or used selectively around entryways, foundations, columns, and chimneys. Exterior stone veneer adds texture and depth, making structures appear more substantial and refined.

Interior Feature Walls

Inside the home, stone veneer is commonly used to create feature or accent walls. Living rooms, dining areas, and entryways benefit from the warmth and character that stone provides. A stone veneer wall can serve as a focal point that anchors the overall interior design.

Fireplaces

Stone veneer is a popular choice for fireplace surrounds. Its heat resistance and natural beauty make it ideal for both traditional wood-burning fireplaces and modern gas or electric units.

Kitchens and Bathrooms

In kitchens, stone veneer can be used for backsplashes, islands, or decorative walls. In bathrooms, it adds a spa-like atmosphere when used around bathtubs, showers (with proper sealing), or vanity walls.

Commercial Spaces

Hotels, restaurants, offices, and retail stores often use stone veneer to convey quality, sophistication, and brand identity. It helps create memorable spaces that feel inviting and durable.

Installation Considerations

While stone veneer is easier to work with than full-depth stone, proper installation is essential to ensure longevity and performance.

Surface Preparation

The substrate must be clean, stable, and capable of supporting the veneer. Common substrates include concrete, masonry, cement board, and properly prepared wood framing. Moisture barriers and metal lath may be required, especially for exterior installations.

Mortar and Adhesives

Stone veneer is typically installed using mortar or specialized adhesives designed for masonry applications. The choice of bonding material depends on the type of veneer, substrate, and environmental conditions.

Joint Styles

Stone veneer can be installed with visible mortar joints or in a dry-stack style with minimal or no visible joints. Each approach creates a different aesthetic, from traditional and rustic to modern and sleek.

Professional vs. DIY Installation

While some homeowners choose to install stone veneer themselves, professional installation is often recommended, particularly for exterior projects. Skilled installers ensure proper drainage, alignment, and structural integrity.

Maintenance and Care

Stone veneer is relatively low-maintenance, but some care is required to keep it looking its best.

Natural stone veneer may benefit from periodic sealing to protect against moisture and stains, especially in kitchens, bathrooms, and outdoor environments. Manufactured stone veneer generally requires less sealing but should still be cleaned regularly with mild detergents and water.

Harsh chemicals, pressure washing, and abrasive tools should be avoided, as they can damage the surface or degrade the mortar joints.

Environmental Considerations

Sustainability has become an important factor in material selection, and stone veneer offers several environmental advantages. Because it uses less raw material than full-depth stone, it reduces resource consumption. Manufactured stone veneer can incorporate recycled materials, further lowering its environmental impact.

Additionally, stone veneer’s durability means it does not need frequent replacement, reducing waste over the life of a building.

Design Trends and the Future of Stone Veneer

As architectural styles evolve, stone veneer continues to adapt. Current trends include larger stone formats, neutral and earth-toned color palettes, and mixed-material designs that combine stone with wood, metal, and glass.

Advances in manufacturing technology are making manufactured stone veneer increasingly realistic, blurring the line between natural and engineered products. Lightweight panel systems and modular designs are also simplifying installation and expanding design possibilities.

In the future, stone veneer is likely to play an even greater role in sustainable and energy-efficient construction, serving as both a decorative and functional component of building envelopes.

Conclusion

Stone veneer represents a perfect balance between beauty, practicality, and innovation. It captures the enduring appeal of natural stone while addressing the demands of modern construction. With its wide range of styles, applications, and price points, stone veneer offers designers and homeowners the freedom to create distinctive spaces that feel timeless and refined.

Whether used to transform an exterior façade, create a dramatic interior feature wall, or add character to a commercial environment, stone veneer remains a powerful design element. Its versatility, durability, and aesthetic richness ensure that it will continue to be a cornerstone of architectural and interior design for years to come.